Smart solutions for your cutting process

Jogging and cutting systems as individual as your requirements

With the presentation of the world’s first and still the only fully automatic jogging and cutting system, baumannperfecta sets new standards in postpress. We offer automation solutions in different expansion stages for digital printing, commercial printing, online printing, packaging printing and label printing, modular and scalable – i.e. for all printing areas and every size of company. From a simple pile lifter to a fully automated and networked complete solution.

Our modules are designed in such a way that they can be used both offline in individual operation and inline, i.e. as a system, in a wide variety of combinations. With the first component you lay the foundation for further expansion in the future. We support you right from the start with a joint, individual concept development, adapted to your requirements, wishes and future plans. The modular concept together with our know-how and many years of experience in the printing industry guarantee you fast development times for tailor-made solutions.

You are looking for new ideas to optimize your postpress?

Then let’s check together whether we can make your cutting process more effective with modern technologies. We and our local representatives will be happy to support you so that you remain competitive or can perhaps extend your lead. Convince yourself what is possible with modern technologies today. We cordially invite you to a live demonstration – on site with us or virtually in a VIP video conference with a live connection in our showroom – also with your own test material.

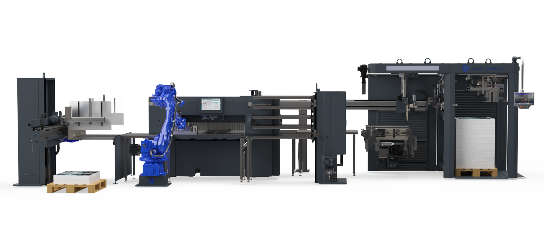

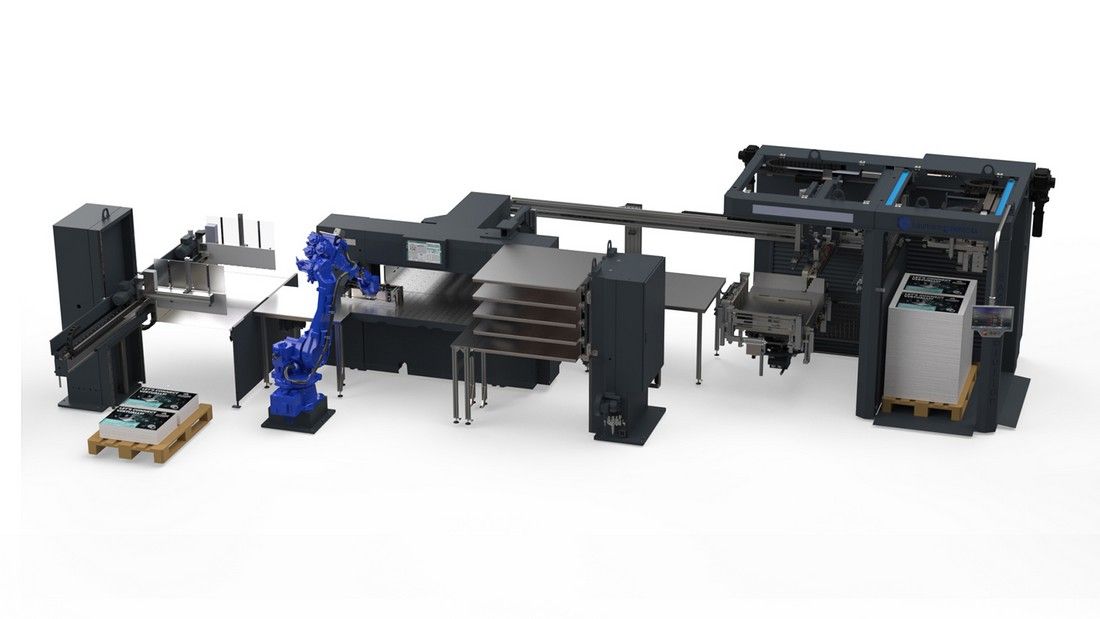

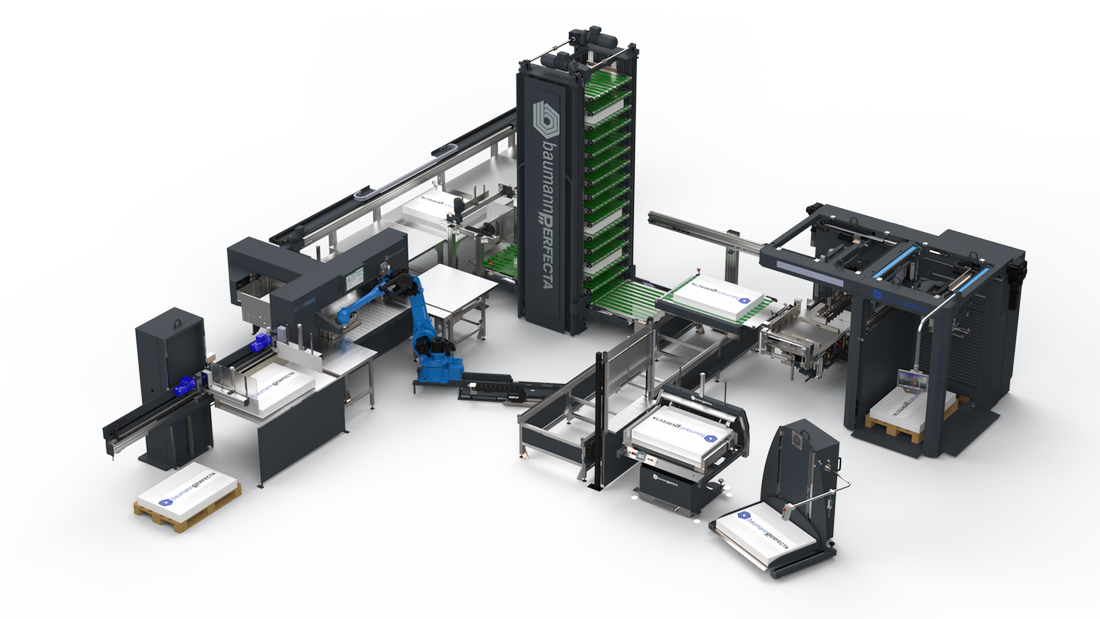

Components (from right to left): Pile Hoist BSH 3-1200, Jogging machine BSB 3L Prof., High speed cutter BP 132 with autoturn system BDG e, Unloader BA 3

Cutting system „Auto4Cut“

The perfect automation solution for your finishing – whether for commercial printing, label production or paper mills.

Workflow

The material to be cut is lifted to the correct working height with the BSH 3-1200 pile hoist and placed in the BSB 3 L Prof. automatic jogger by the operator. After the jogging process, the high-speed cutter is loaded by the loading unit via the front table. The BDG e autoturn system automa-tically cuts the 4 sides of the sheet.

The BP 132 high-speed cutter with AWR (Automatic Waste Removal) increases the productivity even more, as the cutting waste is automatically removed. The front feeder guarantees the highest quality with every cut by aligning the cutter layer at the saddle.

The finished layers are pushed by the operator onto the unloader BA 3, which stacks the single or multiple layers with high precision, while the operator can already jog the next layer.

- Parallel processes jogging and cutting for high productivity

- Reduction of personnel costs

- Ergonomic work due to automatic devices during loading and unloading

- shorter ROI through higher productivity and constant performance

- Minimal set-up times/easy operation

- 2 shift operation

- Jobs with up to 10 cuts

- From 5 cutting layers / job

- Sheet format B3

Pile hoist BSH 3-1200

- Platform size: 830 x 1250 mm

- Max. loading capacity: 1.200 kgs

Automatic jogger BSB 3 L Prof.

- max. format: 800 x 1140 mm

- max. layer height: 160 mm

High-speed cutter BP 132

- max. cutting width: 1320 mm

- min. layer height: 30 mm

- max. layer height: 120 (165) mm

- rest cut without/with false plate: 20/77 mm

Autoturn system BDG e

- max. format: 750 x 1060 mm

- min. format: 480 x 480 mm

- 90 ° turn, including side feeder for left side

Unloader BA 3

- min. format: 400 x 400 mm*

- max. format: 770 x 1070 mm

*The inherent stability of the stack must be given.

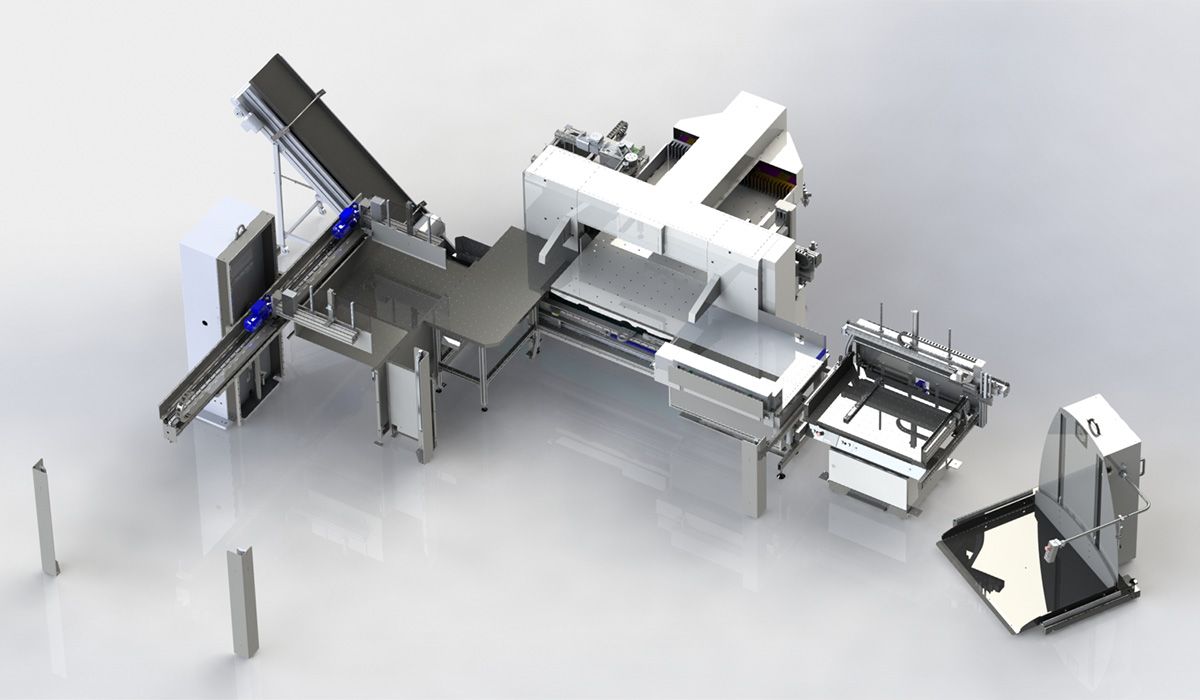

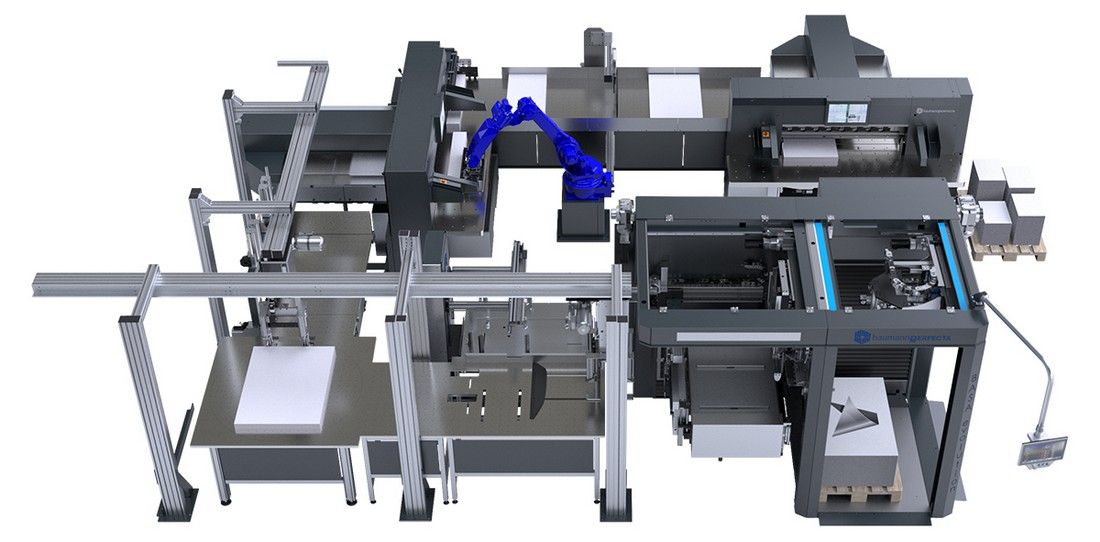

Components (from right to left): BASA Evolution, High speed cutter BP 132, Unloader BA 3

Semi automatic Cutting system

The perfect automation solution for your finishing – whether for commercial printing, online printing and pharmacy.

Workflow

Feeding of the BASA by the operator. Separation and break up of the partial layers and fully automatic jogging of the cutting layer. The machine now processes the entire pallet fully automatically and forms accurately edged layers at the preset height. Partial layer height a nd air supply can be changed individually. An integrated unloading pusher transfers the perfectly jogged, aligned and pressed layers directly to the rear table of the BP 132 high speed cutter.

The BP 132 high speed cutter guarantees an efficient and

ergon omic cutting process.

The modular buffer and conveyor systems ensure sufficient flexibility between the jogging and cutting processes. The BA 3 unloader is loaded by the operator and automatically stacks single or multiple blanks with high precision.

- Fully automatic jogging process

- Parallel processes jogging and cutting for high productivity

- Ergonomic work / less physical stress

- Reduction of personnel costs

- Minimum set

- 2 Shift operation

- Multiple forms/collective forms

- From 5 cutting layers / job

- Sheet format B3

Automatic Jogging system BASA evolution

- min. sheet format: 400 x 600 mm

- max. sheet format: 770 x 1070 mm

- output: up to 25.000 sheets/hour

High-speed cutter BP 132

- max. cutting length: 1320 mm

- max. operating height: 165 mm

- rest cut without/with false clamp: 20/77 mm

Unloader BA 3

- min. sheet format: 400 x 400 mm*

- max. sheet format: 770 x 1070 mm

*The inherent stability of the stack must be given.

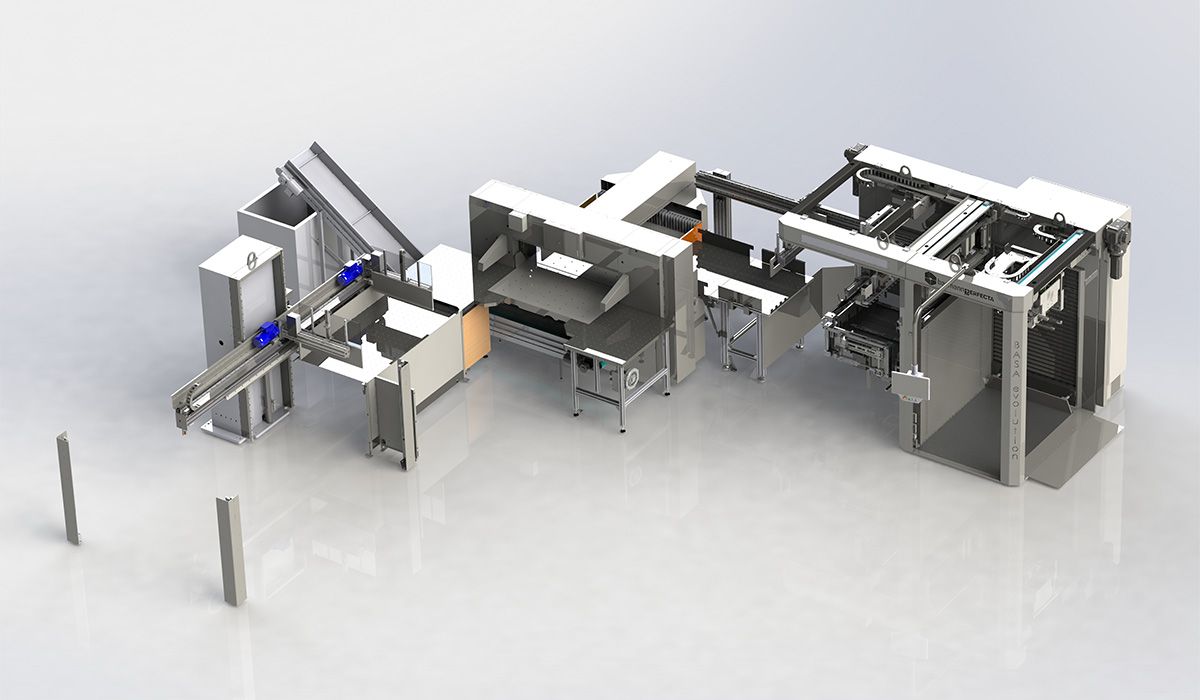

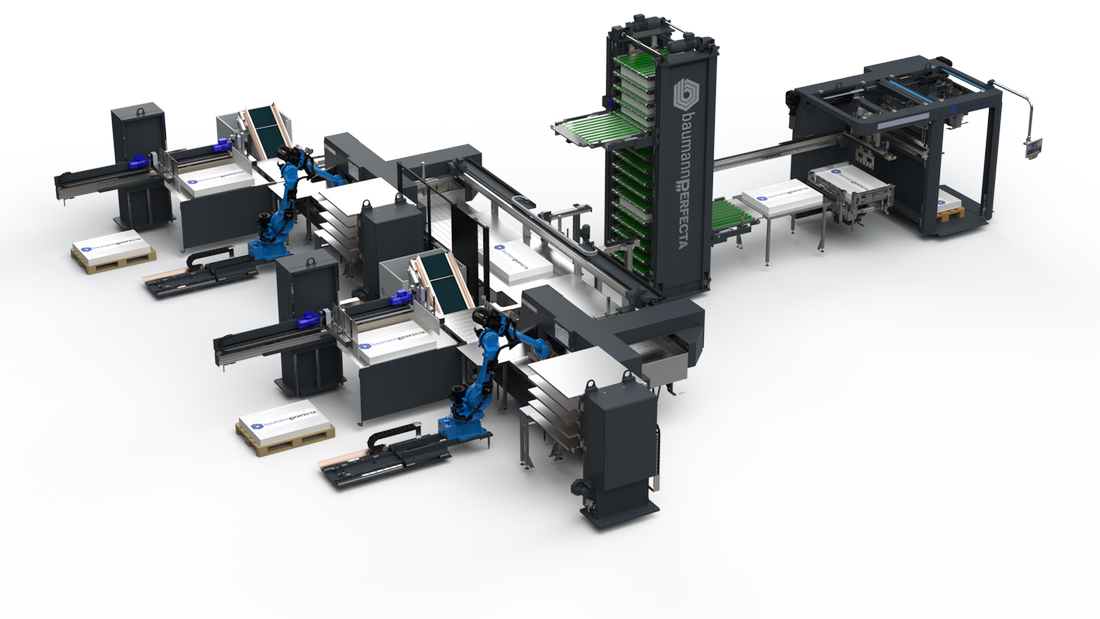

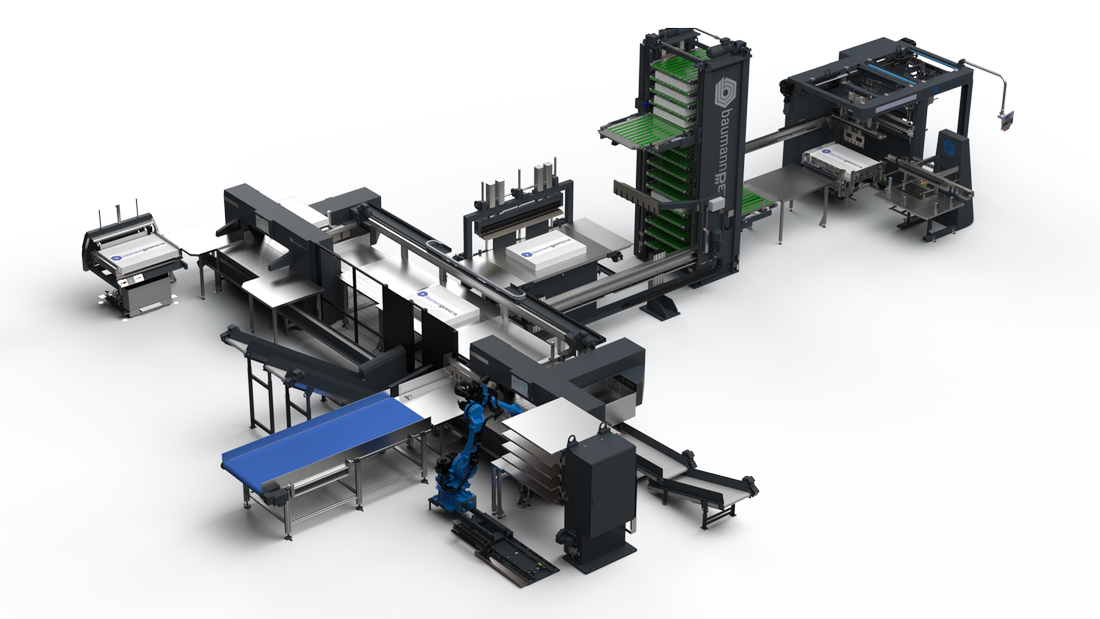

„Independent“ cutting system

The perfect automation solution for your finishing – whether for commercial printing, online printing and pharmacy.

Components (from right to left): BASA evolution, High speed cutter BP 132, RC (Robotic Cutting), BVP (buffer system), Unloader BA 3-S

Workflow

Feeding of the BASA by the operator. Separation and break-up of the partial layers and fully automatic jogging of the cutting layer. The machine now processes the entire pallet fully automatically and forms accurately edged layers at the preset height. Partial layer height and air supply can be changed individually. An integrated unloading pusher transfers the perfectly jogged, aligned and pressed layers directly to the rear table of the BP 132 high-speed cutter.

Unmanned cutting is done by Robotic Cutting RC at this point. All handling processes such as gripping, turning, aligning, tapping or transporting to other processes or machines are handled by the flexible RC.

Of course, the high-speed cutters can also be operated manually. The BVP buffer can also be used to process multiple cuttings. The modular buffer and conveyor systems ensure sufficient flexibility between the jogging and cutting processes. The BA 3-S unloader is fed by the RC and automatically stacks single or multiple products with high precision.

- Fully automatic processing up to the finished cut end product

- Continuous process

- Consistent quality

- Independent production

- Minimum set-up times/ simple operation

- 2 Shift operation

- Multiple forms/collective forms

- From 5 cutting layers / job

- Sheet format B3

Automatic Jogging system BASA evolution

- min. sheet format: 400 x 600 mm

- max. sheet format: 770 x 1070 mm

- output: up to 25.000 sheets/hour

High-speed cutter BP 132

- max. cutting length: 1320 mm

- max. operating height: 165 mm, with RC Robot 130 mm

- rest cut without/with false clamp: 20/77 mm

Robotic Cutting RC

- min. sheet format: 400 x 400 mm

- max. sheet format: 1050 x 1050 mm

- min. format for strips: 650 x 45 mm

- max. format for strips: 1050 x 442 mm

Unloader BA 3-S

- min. sheet format: 400 x 400 mm*

- max. sheet format: 770 x 1070 mm

*The inherent stability of the stack must be given.

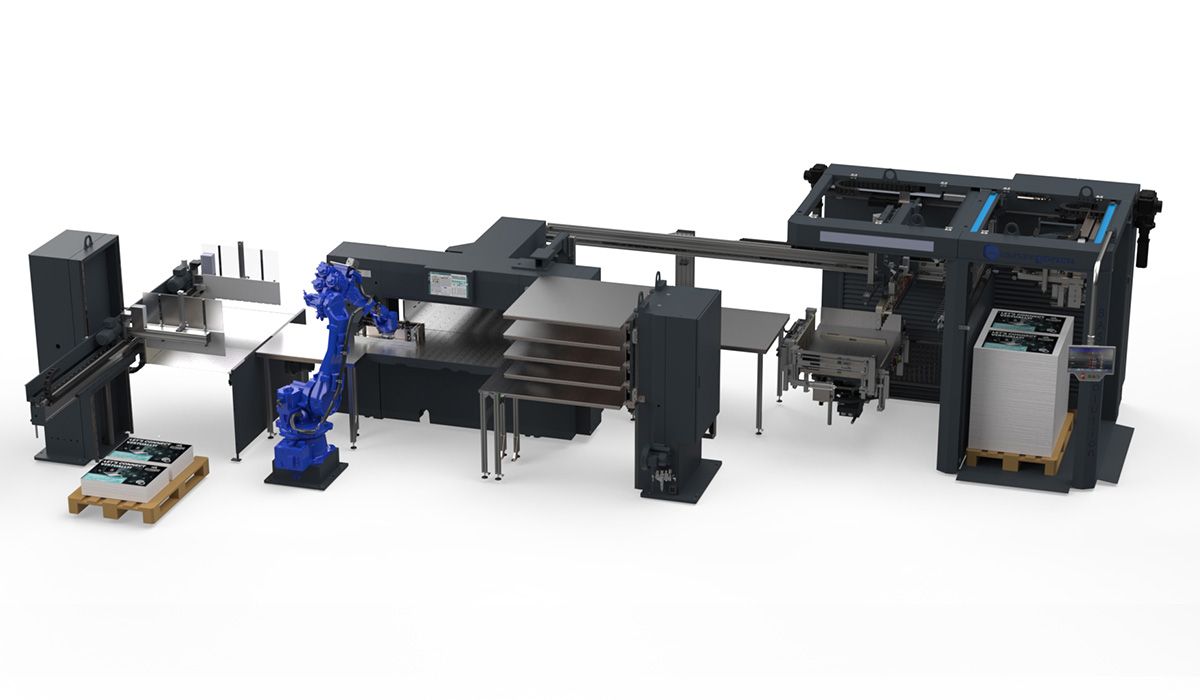

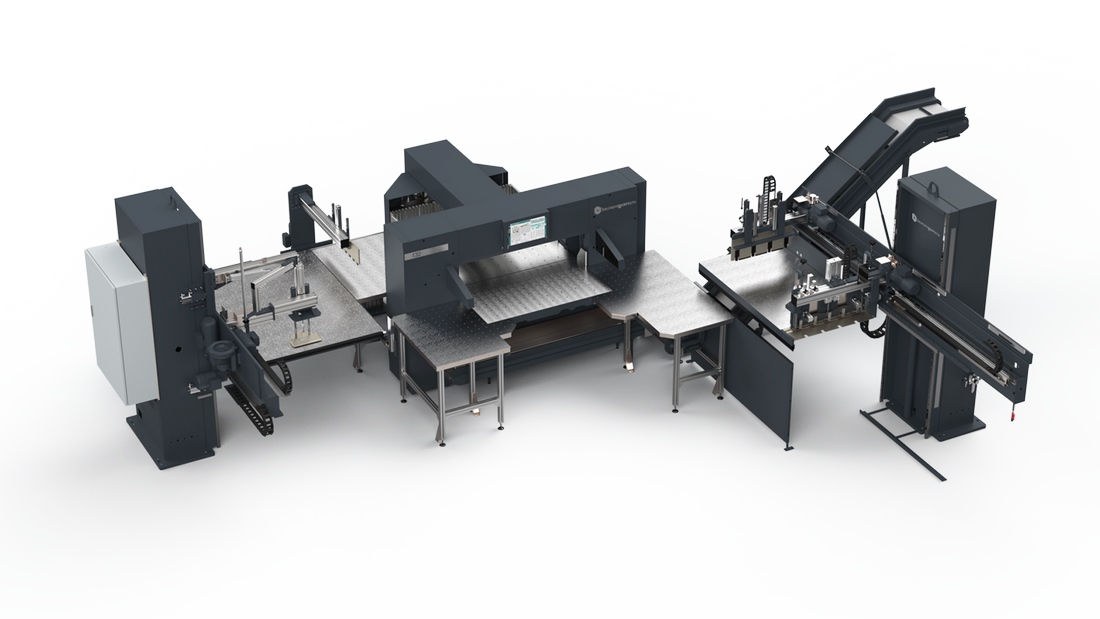

Cutting system impressions:

Fully automatic jogging and cutting line for commercial printing. Consisting of BASA evolution, high-speed cutter 132 with robotics system, vertical buffer and unloader.

Vollautomatisches Schüttel- und Schneidesystem mit der BASA evolution, einem Multi-Regal, einer Lagenverteilung auf zwei Schnellschneidern 132 mit RC Robotic-Lösung, jeweils mit Vertikalpuffer und Ablader für die vollautomatische Verarbeitung – von der Palette mit den Druckbogen bis zum fertig geschnittenen und auf der Palette abgelegtem Endprodukt.

Fully automatic jogging and cutting system for label production BASA evolution with cardboard inserter, turntable, pressing station, high-speed cutter 132 with Robotic RC System and another cutting machine for manual processing. For example, a label die-cutter could also be installed here instead of the second cutting machine.

Cutting system with loader and unloader as well as automatic chip disposal

Fully automatic jogging and cutting system Feeding via BASA evolution or stack lifter with automatic jogger, mobile conveyor belt, multi-buffer, high-speed cutter with robotics system and unloader.

Combination of fully automatic shaking and cutting system with manual BASA evolution system, loading station, multi-rack, squeezing station, distribution to a high-speed cutter with Robotic RC system and a cutting machine with additional manual shaker

Would you like to find out more?

Contact us now!